Introduction

Sewing needles are essential tools for anyone who loves to sew or quilt. These small and seemingly simple tools go through a complex manufacturing

Raw Material Preparation

The first step in making sewing needles is to prepare the raw materials. The main material used is stainless steel or nickel-plated carbon steel. These metals are chosen for their strength, flexibility, and resistance to corrosion.

The steel is melted and then formed into long, thin rods. These rods are then cut into smaller sections, each of which will become a sewing needle.

Wire Drawing and Tempering

Next, the steel sections are passed through a series of machines that draw the wire to the desired thickness. This process involves stretching the wire through a series of progressively smaller holes until the desired diameter is achieved.

After wire drawing, the steel is heat-treated and tempered to optimize its hardness and flexibility. This step is crucial to ensure that the needles can withstand the forces exerted during sewing without breaking or bending.

Pointing and Shaping

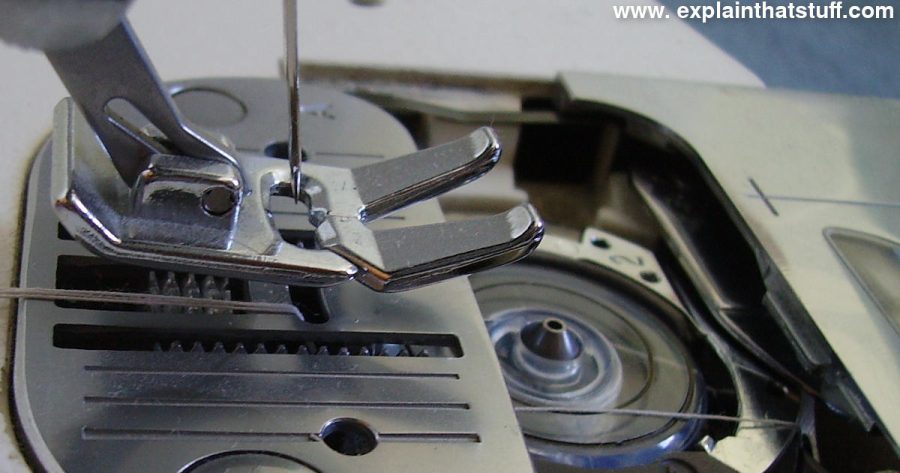

Once the wire is tempered, it is cut into individual needle blanks. These blanks are then pointed and shaped by specialized machines. The tips of the needles are ground to a sharp point and shaped to create the necessary groove for thread passage.

The needles are also flattened and have a hole at one end to accommodate the thread. The process of shaping and pointing the needles requires precision machinery to ensure uniformity and accuracy.

Surface Treatment

To further enhance the durability of the needles and to reduce friction during sewing, they undergo surface treatments. This can involve coating the needles with a thin layer of nickel or chrome, which provides additional corrosion resistance and a smoother surface for thread passage.

Some needles may also undergo additional treatments like polishing or plating to improve their appearance or offer specific benefits, such as reduced needle thread friction.

Quality Control

Before the sewing needles are packaged and made available for sale, they undergo rigorous quality control checks. This process ensures that the needles meet the required standards and are free from any defects, such as burrs or imperfections in the surface.

Only the needles that pass these stringent tests are packaged and distributed to retailers and sewing enthusiasts worldwide.

Conclusion

The production of sewing needles involves a meticulous and precise process to create high-quality tools for sewing and quilting. From raw material preparation to the final quality control checks, every step ensures that these small but essential tools meet the expectations of professional sewers and hobbyists alike.

Next time you thread a sewing needle, take a moment to appreciate the craftsmanship behind it!

Fascinating!

Molly O’Malley: What an inventive process

This is amazing! We can learn a lot from understanding how something so small as a sewing needle comes together. It’s remarkable to see all the tiny, intricate steps that go into its manufacture.

Absolutely incredible!

Wow, this is amazing! Just goes to show all the work and care that goes into creating these tiny tools.