Sewing machines are an essential tool for anyone who loves to sew, whether you’re a professional seamstress or an enthusiastic hobbyist. However, one of the most frustrating issues that can occur while sewing is when the thread keeps breaking. This can lead to a lot of wasted time and effort, not to mention the disappointment of not being able to complete your project. So, why does your sewing machine keep breaking the thread? Let’s explore some possible reasons.

1. Incorrect Thread Tension

One of the common reasons for thread breakage is incorrect tension. If the thread tension is too tight, it can cause excessive strain on the thread, leading to breakage. On the other hand, if the tension is too loose, the thread may not be tightly held in place, causing it to slip out and break. Make sure to adjust the tension settings on your sewing machine according to the type of fabric you are using.

2. Old or Low-Quality Thread

The quality of the thread you use can have a significant impact on its durability. Using old or low-quality thread can make it more prone to breakage. It is always advisable to invest in good-quality thread that matches the type of fabric you are working with. Additionally, make sure to store your thread in a cool and dry place to maintain its integrity.

3. Needle-related Issues

Inappropriate or damaged needles can also contribute to thread breakage. Ensure that you are using the correct type and size of needle for your fabric. A dull or bent needle can cause the thread to fray or snap. Be sure to change your needle regularly to avoid such issues.

4. Bobbin Winding Problems

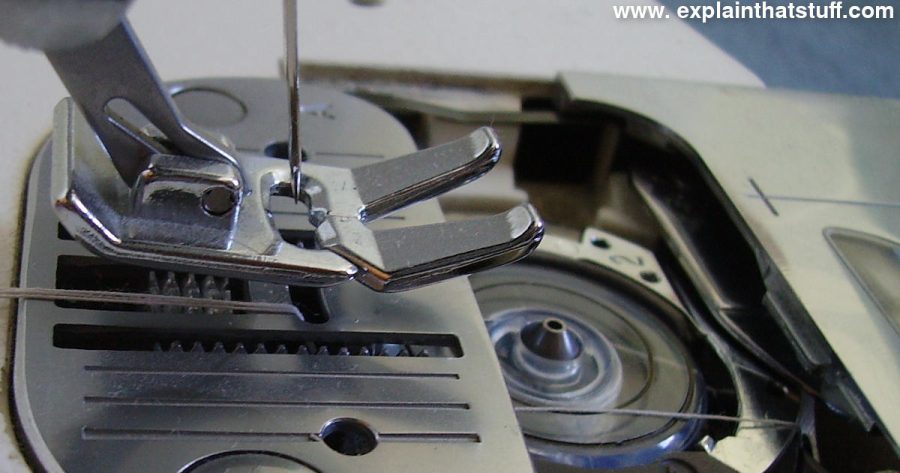

The way you wind the bobbin can affect the smooth flow of thread while sewing. If the bobbin is wound too loosely or unevenly, it can cause the thread to tangle and break. Take care to wind the bobbin correctly, ensuring it is evenly and tightly wound.

5. Sewing Machine Maintenance

A well-maintained sewing machine is less likely to cause thread breakage. Regularly clean and oil your machine as per the manufacturer’s instructions to keep it in optimal condition. Over time, lint and debris can accumulate in the machine, affecting its performance and potentially leading to thread breakages.

Conclusion

Thread breakage can be a frustrating and time-consuming problem while sewing. By paying attention to factors such as thread tension, thread quality, needle usage, bobbin winding, and proper maintenance of your sewing machine, you can significantly reduce the chances of thread breakage. With a little patience and troubleshooting, you’ll be able to enjoy uninterrupted sewing sessions and successfully complete your projects.

Understanding tension settings can help resolve thread breaking issues #tensionsettings #threadbreaking

Liz Thome: Depending on the fabric you use, your machine may be working harder than it can handle #solvethreadbreaking #fabricchoice

Check that your needle is in good condition and is the correct size and type for your fabric #needlesize #threadbreaking

#threadfixing It’s important to know the reasons why machine breaks thread so that you can figure out how to fix it. Looking into the tension settings, fabric choices, and needle sizes can help you determine the issue and solve it.

Additionally, make sure you use the right thread for your fabric and needle size #threadbreaking #threadtype